IIPRD and Khurana & Khurana (K&K), apart from handling core Intellectual Property (including Patent), and…

Hydrogen Fuel Powered Higher Efficiency Internal Combustion Engine

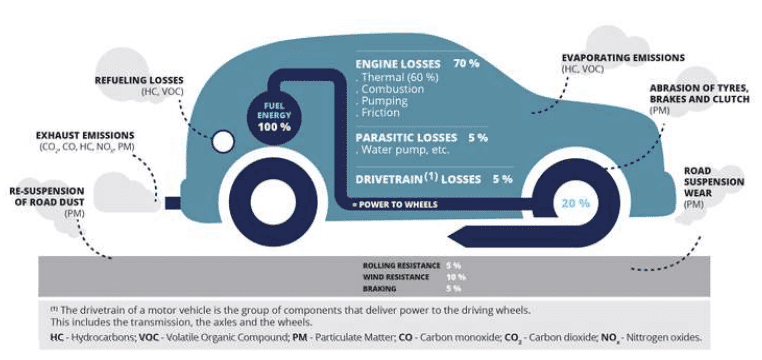

The invention is a unique onboard hydrogen and oxygen generating technology that uses IC Engine waste heat to produce hydrogen and oxygen by using high temperature electrolysis process in distilled water.

Using hydrogen IC engine’s 70% waste heat energy is used to convert distilled water into steam which is then supplied into the hydrogen DSHFG device which separates H (hydrogen) and O (oxygen) from water by the process of high temperature electrolysis method.With this technology the system operates between 100°C and 350°C and takes over 240 – 360 watts of electricity to generate 1kg of Hydrogen.

In comparison, with current technology, the calorific energy content of hydrogen is about 39kwh/kg. Taking in to account the process inefficiencies, it takes over 50kwh of electricity to generate 1 kg of hydrogen.

The invention is an environment friendly technology that reduces or eliminates need for Hydrogen filling station. The technology has application in Electricity production (Industrial and Domestic generators), agricultural pump set, automobile industry, and aircraft and marine engines.Currently 1 kilogram of Hydrogen production costs 1,100 Yen (US$9.85 or INR 700), while the instant technologytechnology can bring the Hydrogen production cost down to 30 Yen (US$ 0.28 or INR 20).

For further information about the technology you can refer to:https://www.iiprd.com/wp-content/uploads/2020/08/Tech-Licensing-Proposal-Hydrogen-Fuel-Powered-Higher-Efficiency-IC-Engine.pdf